M Series 2018 | Tough Questions from Pinkbike

In December 2017, we invited editors from Pinkbike, the world’s largest and most influential MTB website, to our offices and manufacturing facility in Ogden, Utah, just north of Salt Lake City. We were excited to have one of their most talented and skeptical writers, Vernon Felton, come and see our facility in person. We are proud of our new facility, the products hand crafted here, and we wanted to expose ourselves to Pink Bike’s vast audience. But they warned us, “Hey we are not coming here to shoot an advertisement, we are coming to ask ENVE some tough questions!” And then added, “Can you handle it?”

We answered with our hearts, and maybe a little pride: “Yes! Of course, bring it on!” When you have a great brand, talented employees and a best in class product line, you relish any chance to tell your story. But we must admit, we were a bit nervous. The commenters on Pinkbike are famous for their aggression and caustic remarks, while at the same time generally reflecting prevalent attitudes in the market. These are tough customers and premium brands are a favored target. We were absolutely guaranteed to read negative feedback, crude jokes and multiple diversions into completely unrelated brands and products. But we love riding and the products that we’ve developed, so the heart won out.

It was a good call. The visit was great, the crew from Pink Bike is highly professional and we had two full days of great conversation. Check it out here. Vernon did his best to trim it down without losing sight of his objective or losing the attention of his readers and viewers. But, with so many hot topics and technical discussions, our phone started ringing off the hook with people wanting to know more. As it turns out, Vernon’s questions proved extremely interesting to many in the mountain bike community. If you were one of those readers looking for a bit more detail and clarification, read on.

Question #1 – What does your rim strip do that others don’t?

Other rim strips simply seal the air chamber. No other rim strip absorbs and dissipates energy like our patent pending Protective Rim Strip. The increased surface area lowers the pinching stress by spreading it out. The material deforms to the profile and imperfections of the object, reducing stress risers and absorbing energy. It is the difference between cutting with a sharp knife on a butcher’s block, and cutting with a dull knife on a rubber mat. The dull knife/rubber mat will take a significant increase in force to make the same cut.

Deep Dig Version, Question #1 – The new M Series bead is wider than its first-gen predecessor: 1.2mm (or 36%) wider in the case of the Wide Hookless Bead found on M5 and M6 series, and 1.7mm (or 52%) wider on the Protective Rim Strip found on M7 and M9 series rims. How does gaining 1.7mm completely eliminate pinch-flats in your testing? It sounds crazy.

Reducing pinch-flats is about absorbing energy and dissipating impact forces. One piece in the solution is increasing the contact area by using a wider sidewall to reduce the pinch force. But the total solution also involves the profile of the sidewall which can now be built with a much larger radius which reduces the localized stress and the tendency to cut into the tire rubber. This is your dull knife. The shape of the sidewall and the shape of the rim cross-section are also designed to absorb energy which reduces the force behind the dull knife. For our gravity products, we took it a step further and created the Protective Rim Strip which is able to deform and absorb even greater levels of energy. In fact, using the Protective Rim Strip it is impossible to generate enough force to pinch the sidewall without destroying the wheel. If you do take an impact that cracks the rim, your tire will retain air pressure and you’ll be able to finish your race or ride.

Question #2 – Why were the original M Series wheels so stiff?

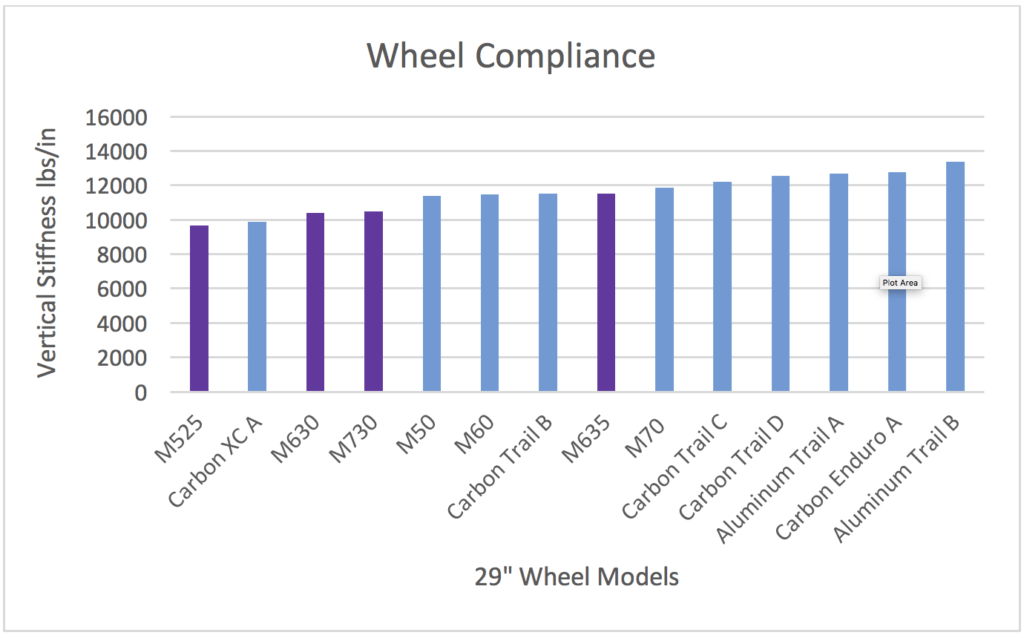

The original M Series was stiffer vertically than the new M Series. Looking back, some riders might say that those wheels were a bit too stiff, but these subjective comparisons can be deceiving if you don’t have all of the information. Let’s look at the details. There is good stiffness and bad stiffness. Our riders love the acceleration and cornering provided by ENVE’s wheels. When we ride test with professionals, they time and again choose the stiffest lacing pattern (2x) over a more vertically compliant (3x) lacing. We choose to build wheels this way. But consider, not all ENVE wheels are the same, our previous M60 series was lighter duty compared to our M70 series. That does not mean that rider A or website B would not do a test between our 30mm M70 and another 30mm carbon trail wheel. Because our wheels are so light, they might even have weighed the same. But our M70 was designed for an aggressive gravity rider and the M60 was not. In short, they ride differently. One of the big steps forward with the new M Series is that the rim’s width no longer dictates stiffness or strength like it does with our competitor’s offerings. We now offer 30mm rims in three different strength (and therefore stiffness) levels. Stiffness matters, but only objective comparisons are insightful. Take a look at the graph here. The much maligned M70 is not, in fact, any stiffer than wheels that have received high marks for ride quality.

Our wheel compliance chart rates wheel stiffness. Data is collected in the test lab by placing a vertical load on the axle and measuring axle displacement as loads are increased. Presented as an effective spring rate, a 10,000 lb rating, means a 10,000 lbs load would result in the axle moving 1 inch. Just like with suspension components, a higher rating equals a stiffer ride.

What’s important to understand is that all carbon wheels are inherently stiff, so pinch-flatting is an intrinsic side effect of hookless carbon construction. ENVE developed the Protective Rim Strip as a solution to this known issue that plagues all wheel manufacturers, not as a solution for a problem related to a specific wheel in our line-up.

Deep Dig Question #2 – When ENVE first came out the storyline was that ENVE’s carbon wheels were a finely tuned balance of lateral stiffness and vertical compliance, but compared to a lot of carbon wheels on the market they are significantly stiffer and could even be called harsh. This was particularly true with the advent of the 2014 M Series models. Some people like that. Some really don’t. What are you aiming for with the degree of stiffness?

For this question, I think it’s important to put stiffness in perspective. There is good stiffness and bad stiffness. In 2014, we were very focused on making carbon wheels that were extremely durable and we were still compensating for stiffness deficiencies in the wheel geometry by making the rim stiff. When the M Series debuted, the challenge was to build a 29” wheel on a 135mm hub that would be lightweight, accelerate like a rocket, corner predictably, and maintain a tubeless seal. The price was a slightly stiffer wheel vertically, but tire and suspension settings could mitigate negative effects for the majority of riders. Trail riders weren’t sold on carbon. The leading OEs were turning the tide on carbon frames, but the wheel market was not really there. Fast forward to 2016 and dudes are charging on 170mm-travel bikes with carbon rims and realizing that rim tuning could provide significant benefits. We were there, too, but we were working on something remarkable that would reset the MTB world’s expectations of what a wheel, made from any material, could be. We had to be patient, and we appreciate that our customers were as well. The new M Series is thoroughly modern. It addresses stiffness per application and in terms of ride quality it’s a night and day difference over the previous generation M Series. Our experience, new technologies and standards, and time have led us to a new line of wheels that are both stiff and compliant in all the right ways.

Question #3 – The impact test. Is it valid?

An impact is a nearly instantaneous transfer of energy from one object to another. The purest way to translate energy and to quantify the impact is to hold one of the objects completely stationary. Wheels in our test fixture cannot rotate, or rebound in any way to diminish the impact force. Trail impacts are different because there is always energy absorbed by the bike’s suspension and the rider. We ride test and race test in order to calibrate our test fixtures and set our minimum impact thresholds. There is no doubt that the test is valid and accurate. We have seen that when we qualify wheels against our standards, they perform to our expectations in the field. However, because these loads are derived from experience and not calculated in theory, there is also no way to prove that it exactly replicates any certain field impact, nor is it relevant. It comes to life when you test products on the fixture that you ride in real life. If we were to show you an aluminum rim on that fixture, and you witness the damage, those numbers gain credibility because you have felt that rock and seen that ding and have calibrated your expectations. We have done the same thing, except our relevant experience is with carbon.

Deep Dig Question #3 – How did you determine, when creating your pinch-flat testing protocols, the threshold for pinch-flatting? Some people, for instance, have looked at the drop test apparatus you displayed at Eurobike and said, ‘Meh. A rider’s weight is so much greater than the 50-pound weighted mandrel combo that Enve drops onto the new M Series rims.’ Is your test an accurate means of replicating pinch-flat worst-case scenarios and how did you arrive at that protocol? How do you know your pinch-flat threshold is accurate?

Note: ENVE launched the new M Series to the world at Eurobike 2017. In our booth at the tradeshow, we displayed an impact fixture so we could demonstrate, successfully, that the tire could not be pinched. This fixture was scaled and modified for shipping and ease of use. That fixture used a lighter weight (about 50lb) compared to our test lab fixture (about 85lbs) and the heights were raised accordingly. We used energy calculations to adjust the numbers. That fixture is referenced in the question, but all of our test data is collected on our 85lb test lab fixture.

We’ve been doing impact tests on carbon wheels for over 10 years. The nature of these impact tests is that at a certain point you pinch-flat the tire. So since our first mountain wheels were developed, we’ve been recording the impact height at which our test tire pinch-flats. So we had a baseline of where tires pinch in the lab and a basic understanding of frequency in the field.

In developing the new M Series, we didn’t really know getting started what the thresholds needed to be other than “better.” However, out of the gate testing the strip, we were unable to pinch-flat the tire in our standard lab impact tests so we knew we were on to something meaningful. Following initial lab testing, we provided the technology to our worst known pinch-flat offenders (primarily enduro racers) to see how the technology performed for them. In no time, they had all reached out to express their excitement in the technology because for the first time in years, they’d gone a particular number of rides or days without a flat. At this point we said, “Let’s set the target as ‘unpinchable’.” In the same vein, the wide hookless concept also showed significant improvement over the first generation M Series. From there, we began riding and testing in the real world. Sure, we could also target ‘unpinchable’ for the trail wheels, as well as the gravity product, but there are still a lot of riders who have no issues with flats and love the feel of our lightest wheels. For trail wheels we chose ‘nearly unpinchable’. So our M6 and M5 resist pinching until at or near the threshold for impact toughness, and our M7 and M9 will hold air long past the point of rim damage.

Question #4 – We have all seen broken ENVE wheels. What’s up with that?

Talk about a tough question! I guess we asked for it. When you are racing and winning World Cup Downhills on the world’s toughest courses, it might tend to elevate expectations. And I can imagine many riders taking it as a point of pride that they are tougher on their gear than anyone can handle, even ENVE. We appreciate that, we earned it, and we accept it. It’s under this pressure and with respect to these expectations that we have created our new M Series, which is quite literally a generation ahead of anyone else.

Deep Dig Question #4 – At this price people are expecting your wheels to be nigh-on indestructible. And yet…I think we’ve all heard anecdotes or seen social media posts of people breaking or cracking ENVE rims. Maybe your breakage rate isn’t higher than other manufacturers and we are only hearing about it because it seems noteworthy to people (due, again, to the high sticker price). What is your actual return/failure rate?

Our return rate is less than 2% of all wheels ever sold. Pretty low. It is interesting that anyone would have an expectation of indestructability from a high performance part. ENVE wheels are really quite the exception when it comes to durability because they are not disposable and do offer leading levels of durability and toughness when many performance parts in the world are in fact both very expensive and not necessarily more durable or reliable. We could certainly make a wheel that was impossible to destroy: our DH wheels sell for the same price as our Trail and XC wheels. You could say that we have always offered wheels that are, in fact, indestructible. But in reality, that is not what riders want. What riders want, desperately, is confidence in their equipment and it is logical that paying more would double or triple that confidence. In developing the M Series, this concept drove our development more than any other feature, specification or rider benefit. We encourage people to go the other way, to purchase optimistically, knowing that if they do crack a rim during their ride we will replace it at no cost to them. With the new M Series we are challenging ourselves to go one better, get people on wheels that are always strong enough and then, by removing the most common type of flat, reducing those carbon impacts by a significant margin. We will still cover you if you ever break a wheel, but confidence in an eventual replacement and confidence on the trail are not the same thing. Anyone can replace a rim, no one can replace that lost ride.

Question #5 – What is with the cost of ENVE? Couldn’t you save money building in Asia?

Let’s start with the second question. Could we save money building ENVE wheels in Asia? No. And the reason is simple: you can’t get an ENVE wheel in Asia. Our raw finish requires a nearly perfect part out of the mold every time. What mass producer would ever accept a contract that did not allow patching, filling and reworking of less-than-perfect wheels and selling them at full price? We use exclusive processes and techniques that we refuse to teach to Asian vendors. Even if we did relent, they would be loath to adopt the added cost and man-hours required to make an ENVE wheel.

The cost of an ENVE wheelset reflects a US-made rim, a best-in-class hubset, premium spokes and build quality, top notch support at the best shops around, generous warranty terms, and a no-questions-asked replacement policy for impact damage. We are there every step of the way. This cost also reflects the design work of industry leading minds in bicycle technology, carbon fiber production, aerodynamics and evaluation as well as input from the top athletes in every discipline and real world abusive competition at the highest level including the Tour de France, the Olympics, the World Cup, EWS, and World Championships. When you consider everything that goes into creating a single ENVE wheel it is a surprise they don’t cost more. But in the most important ways, it isn’t about price at all. We dream big at ENVE, not because we are different or better than our customers but because we are just like them. Our riders dream of adventures, destinations and mountain tops all over the world. They train hard and make the sacrifices to dedicate time to the world’s greatest sport. These are not ‘good enough’ dreams, these are amazing dreams. Amazing rides, amazing locations, amazing friendships, amazing bikes and, you guessed it, amazing wheels.